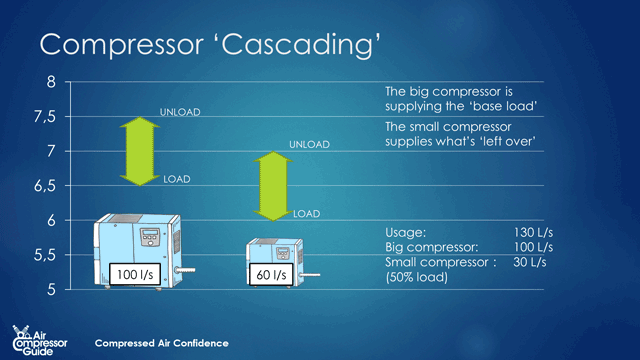

In my last article, I quickly mentioned some of the energy wastes in compressed air systems. One of those was "inefficient compressed air production"? What do I mean by that? It all comes down to the following: Compressors are dumb. Yes, even those brand new compressors with LCD displays and 100s of settings. They are still dump. They do whatever their computer program tells them to do. Most compressors just look at the pressure and act accordingly: Low pressure reached = start compressor. High pressure reached = stop compressor. And to be honest, I wouldn't know a better easy way to control a compressor (without some artificial intelligence super computer). In the end, the pressure is all that matters. Are you producing efficiently? But there is 'producing compressed air' and there is 'producing compressed air efficiently'. For example, lets say we have a setup of two compressors: a big one and a small one. During high-demand hours (day shift), the big compressor runs at full load 100% of the time. The small compressor is a 'trim' compressor: It loads and unloads according to the system pressure. All this is setup by simply setting the pressure on the big compressor a little higher and on the smaller trim compressor a little lower. It's called 'cascading'. Standard setup.  (screenshot taken from my Compressed Air Confidence Course) In fact, this is how 90% of the multi-compressor systems are configured (unless they use a central controller). Quite an efficient setup when running as intended: The big compressor runs fully loaded all the time. And the small compressor loads, unloads, starts and stops. It's more efficient to start and stop a small compressor than a big compressor. And it costs less energy to run a small compressor unloaded, than a big compressor. All great. Until... But now the night shift comes in.. and they take it a little easier. They only use 50% of the compressed air that the day shift uses. What happens? The small compressor COULD take the demand by itself. But instead, it's the BIG compressor will do all the work: load, unload, start, stop. Why? Because the smaller compressor operates at the lower pressure settings. The pressure never drops low enough for the small compressor to start up. The small compressor is just standing there, doing nothing.

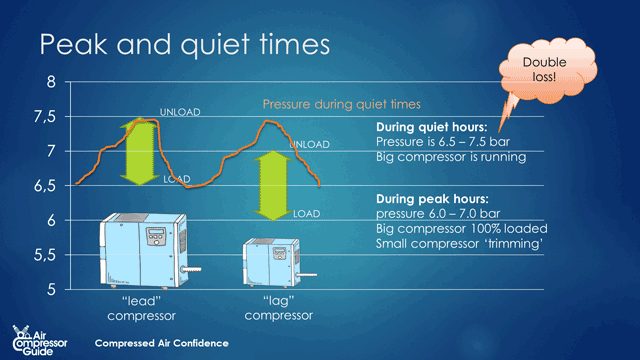

(screenshot taken from my Compressed Air Confidence Course) In fact, this is how 90% of the multi-compressor systems are configured (unless they use a central controller). Quite an efficient setup when running as intended: The big compressor runs fully loaded all the time. And the small compressor loads, unloads, starts and stops. It's more efficient to start and stop a small compressor than a big compressor. And it costs less energy to run a small compressor unloaded, than a big compressor. All great. Until... But now the night shift comes in.. and they take it a little easier. They only use 50% of the compressed air that the day shift uses. What happens? The small compressor COULD take the demand by itself. But instead, it's the BIG compressor will do all the work: load, unload, start, stop. Why? Because the smaller compressor operates at the lower pressure settings. The pressure never drops low enough for the small compressor to start up. The small compressor is just standing there, doing nothing.  (screenshot taken from my Compressed Air Confidence Course) The orange line is the system pressure during quiet times... the pressure never drops far below the lower setpoint of the big compressor (6.5 bar), because it is big enough to handle the air demand by itself. As a result, the small compressor is stopped. It's a waste of energy! In fact, it's a double waste of energy: * The big compressor is running, while the small compressor could do it more efficiently. Small compressors use less energy when running unloaded. The big compressor will likely run at about 50% capacity. Which is about the worst operating point energy-wise. * The system operates at the pressure setpoints of the big compressor. At peak load, the pressure band is between 6 and 7 bar. The pressure settings of the smaller compressor. At quiet times, the pressure band is between 6.5 and 7.5 bar. The pressure settings of the bigger air compressor. That's 0.5 bar extra pressure than we actually need. And that's a waste of energy and money. In fact, it could cost us thousands of dollar per year! A more intelligent central controller can fix problems like this. It can watch the pressures and the air demand and then decide which compressor is best to use. It depends on the size of the air compressors. On the amount of air consumed at different times during the day. On the actual pressure, on the rate of change of pressure, etc. It will even take into account the time a compressor needs to startup and load. But even without a central controller we can optimize and fix the worst of problems. Some TLC With some love and care for your compressed air system, you can see these problems yourself. Take your favorite drink and a chair and watch the compressors load and unload for, say, 20 minutes. Do this at different times of the day. You will see the patterns. And you will spot problems like in the example above. But there are many similar problems: Sometimes a big compressor is started because it's lower setpoint is reached. But before it is completely started up and loaded (it can take 20 seconds for a big compressor), the pressure has already reached it's higher setpoint. The compressor never does any work! it just starts up, runs unloaded and stops. Another example: Two compressors of similar capacity are 'fighting' to be in control. Sometimes the first compressor loads first, another time the second. Sometimes they both start up and load and unload together. There are many more examples... Sit back and relax Just sit in your compressor room and notice what those compressors are doing. Many times, there is a simple solution, like adjusting the pressure settings. Little things like this can literally save you thousands of dollar per year! There is no problem! Or so it seems.. I have seen things like this so many times. Thousands of dollars are wasted, for nothing. As long as the pressure on the factory floor is high enough, people don't think about their compressed air systems. There is no problem! Only when the pressure drops or when there's water or oil in the air, people on the work floor start complaining. Nobody complains about a compressor that's wasting money. Because nobody notices! But on average, 15% of a factories energy bill comes from air compressors! There's a huge potential here to save money! Compressed air training courses That's why it is so important to train employees in the correct use of compressed air. If they see a compressor that is just running unloaded the whole day (yes, I have seen it...) they will know this is not normal and shut it down, or adjust some the settings and make it better! And that's why I have put a lot of focus on the cost of compressed air in my Compressed Air Confidence Course. (a beginners course that teaches the fundamentals of compressed air systems). Just a little knowledge of compressed air systems, combined with a weekly routine (checking the temperatures, pressures, running hours, etc) goes a long way. Click here for more info about the Compressed Air Confidence Course

(screenshot taken from my Compressed Air Confidence Course) The orange line is the system pressure during quiet times... the pressure never drops far below the lower setpoint of the big compressor (6.5 bar), because it is big enough to handle the air demand by itself. As a result, the small compressor is stopped. It's a waste of energy! In fact, it's a double waste of energy: * The big compressor is running, while the small compressor could do it more efficiently. Small compressors use less energy when running unloaded. The big compressor will likely run at about 50% capacity. Which is about the worst operating point energy-wise. * The system operates at the pressure setpoints of the big compressor. At peak load, the pressure band is between 6 and 7 bar. The pressure settings of the smaller compressor. At quiet times, the pressure band is between 6.5 and 7.5 bar. The pressure settings of the bigger air compressor. That's 0.5 bar extra pressure than we actually need. And that's a waste of energy and money. In fact, it could cost us thousands of dollar per year! A more intelligent central controller can fix problems like this. It can watch the pressures and the air demand and then decide which compressor is best to use. It depends on the size of the air compressors. On the amount of air consumed at different times during the day. On the actual pressure, on the rate of change of pressure, etc. It will even take into account the time a compressor needs to startup and load. But even without a central controller we can optimize and fix the worst of problems. Some TLC With some love and care for your compressed air system, you can see these problems yourself. Take your favorite drink and a chair and watch the compressors load and unload for, say, 20 minutes. Do this at different times of the day. You will see the patterns. And you will spot problems like in the example above. But there are many similar problems: Sometimes a big compressor is started because it's lower setpoint is reached. But before it is completely started up and loaded (it can take 20 seconds for a big compressor), the pressure has already reached it's higher setpoint. The compressor never does any work! it just starts up, runs unloaded and stops. Another example: Two compressors of similar capacity are 'fighting' to be in control. Sometimes the first compressor loads first, another time the second. Sometimes they both start up and load and unload together. There are many more examples... Sit back and relax Just sit in your compressor room and notice what those compressors are doing. Many times, there is a simple solution, like adjusting the pressure settings. Little things like this can literally save you thousands of dollar per year! There is no problem! Or so it seems.. I have seen things like this so many times. Thousands of dollars are wasted, for nothing. As long as the pressure on the factory floor is high enough, people don't think about their compressed air systems. There is no problem! Only when the pressure drops or when there's water or oil in the air, people on the work floor start complaining. Nobody complains about a compressor that's wasting money. Because nobody notices! But on average, 15% of a factories energy bill comes from air compressors! There's a huge potential here to save money! Compressed air training courses That's why it is so important to train employees in the correct use of compressed air. If they see a compressor that is just running unloaded the whole day (yes, I have seen it...) they will know this is not normal and shut it down, or adjust some the settings and make it better! And that's why I have put a lot of focus on the cost of compressed air in my Compressed Air Confidence Course. (a beginners course that teaches the fundamentals of compressed air systems). Just a little knowledge of compressed air systems, combined with a weekly routine (checking the temperatures, pressures, running hours, etc) goes a long way. Click here for more info about the Compressed Air Confidence Course

Comments

No comments yet…

Log in or create an account to make a comment...