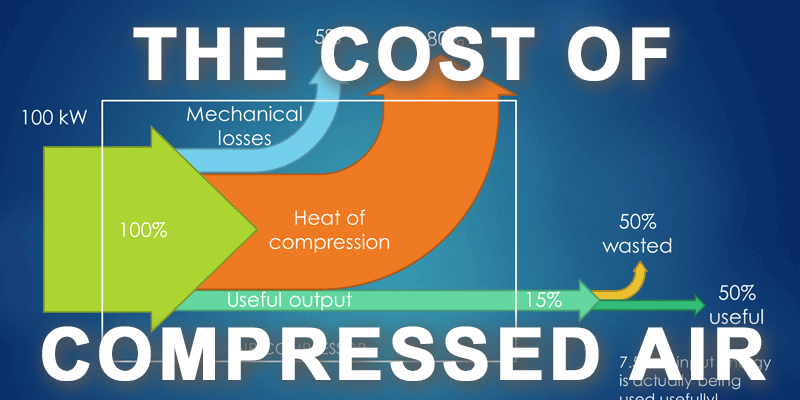

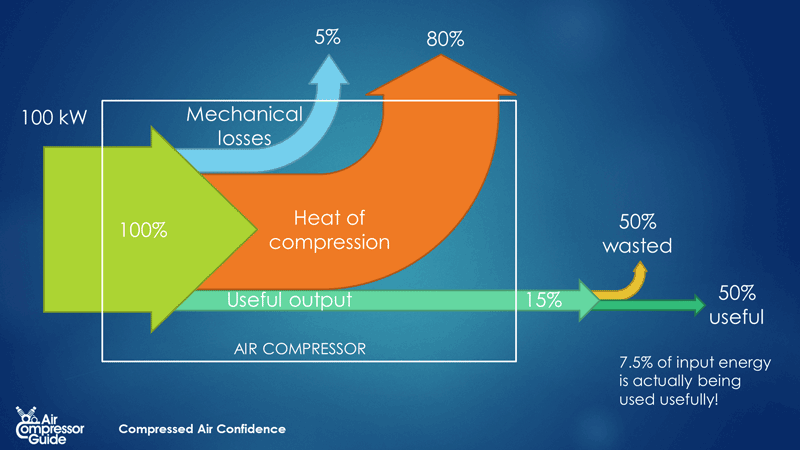

In my last article I talked about the cost of compressed air. And that you must ask yourself: do I REALLY need to use compressed air for my application? http://www.air-compressor-guide.com/blog/using-com... You see, compressed air is about 7 to 8 times more expensive than electricity. And this is something that you should remember any time you use compressed air for anything! In fact, this is why proper training of employees in the use and maintenance of compressed air systems is so important! Because the '8 times more expensive' is just the beginning. A lot of compressed air is wasted AFTER it is produced. We need to make the people that work with compressed air every day aware of the cost of compressed air, and the simple things we can do to save it. So the questions comes up: why is compressed air so expensive? Let's take a look at the energy input and output of an air compressor. Air Compressor energy input and energy output Here is what's called a 'Sankey Diagram' of the energy input and output of an air compressor  On the left you see the energy input. It's set at 100%. And as an example, I added '100 kW' but it could just as well be 50 kW or 600 kW. Our first loss happens when converting electrical energy to mechanical energy (movement). In other words: an electric motor is used to turn the screw of the compressor. This always creates some losses because of friction and other 'resistance': the small blue arrow. (or move the pistons up and down, but this article is about rotary screw compressors) But the loss is only 5%, which isn't THAT bad, especially compared to what's about to come.. The next step is the compression of air. Compression of air: heat This is where a huge 80% of energy is lost: the big red arrow. Compression creates heat. We need to get rid of the heat otherwise the compressor will overheat and melt down. This is by far the biggest loss. And this is also a HUGE opportunity for us to win some of that energy back: 'heat recovery' I will talk more about heat recovery and how to use the heat of compression in a useful way in a later article. For now, let's assume this heat is wasted. In fact, on 95% of installations I have seen in my life.. there was no hear-recovery implemented. The heat was simply wasted. In fact, this is a problem by itself: getting rid of the heat. Overheating is one of the biggest problems with air compressors! So what we get out of the compressor is only 15% of what we put in. But we're not there yet! What we have now is just a steady supply of compressed air. And that has already cost us 6.66 times more than the electrical supply. (100% / 15% = 6.66) Next, we need to clean the air: remove dust, remove water, remove oil. Then we need to transport the air to the point of use. And then we will finally use the compressed air for something useful... hopefully! Energy wasters Here are some of the most notorious energy wasters in your compressed air system:

On the left you see the energy input. It's set at 100%. And as an example, I added '100 kW' but it could just as well be 50 kW or 600 kW. Our first loss happens when converting electrical energy to mechanical energy (movement). In other words: an electric motor is used to turn the screw of the compressor. This always creates some losses because of friction and other 'resistance': the small blue arrow. (or move the pistons up and down, but this article is about rotary screw compressors) But the loss is only 5%, which isn't THAT bad, especially compared to what's about to come.. The next step is the compression of air. Compression of air: heat This is where a huge 80% of energy is lost: the big red arrow. Compression creates heat. We need to get rid of the heat otherwise the compressor will overheat and melt down. This is by far the biggest loss. And this is also a HUGE opportunity for us to win some of that energy back: 'heat recovery' I will talk more about heat recovery and how to use the heat of compression in a useful way in a later article. For now, let's assume this heat is wasted. In fact, on 95% of installations I have seen in my life.. there was no hear-recovery implemented. The heat was simply wasted. In fact, this is a problem by itself: getting rid of the heat. Overheating is one of the biggest problems with air compressors! So what we get out of the compressor is only 15% of what we put in. But we're not there yet! What we have now is just a steady supply of compressed air. And that has already cost us 6.66 times more than the electrical supply. (100% / 15% = 6.66) Next, we need to clean the air: remove dust, remove water, remove oil. Then we need to transport the air to the point of use. And then we will finally use the compressed air for something useful... hopefully! Energy wasters Here are some of the most notorious energy wasters in your compressed air system:

- Air leaks

- Pressure drop

- Inappropriate use

- Artificial demand

- Inefficient air production

I will create separate articles on each one in the future and link to them from here. Here's a very quick intro to each of them. (and there are some more, less known, energy wasters.. more on that in a later article...) Air Leaks It is estimated that 10 to 30% of compressed air is wasted through air leaks. In big heavy-industry type factories... 50% wasted through air leaks is very much possible. Pressure drop Every obstacle in out system creates a pressure drop: air dryers, filters, valves, even the piping itself. The problem is that our machinery need a certain minimum air pressure. So to compensate for the pressure drop, we need to set our air compressor to a higher pressure, which costs more energy! Inappropriate use That's all the time compressed air is used when there's a better (or equal) other option available. Artificial demand A fancy word for 'using a higher pressure than actually needed'. For example, your machine might need 6.5 bar to operate. But it operates at 7.5 bar! That extra 1 bar is not needed and is a waste of energy. And as a bonus: any leaks in the system will leak at 7.5 bar instead of 6.5 bar .. which means you will lose even more energy to compressed air leaks! Inefficient air production In the Sankey diagram above (and in the calculations in the previous post), we made one assumption: that the compressor is running at full load all the time. But this is not the case. In reality, the compressor will stop and start sometimes. It will run unloaded for some time. Air demand and pressure will fluctuate. In the worst case, the compressor might use DOUBLE the amount of energy than in above comparison! And that's just because it is running unloaded for a long time. Or the compressor is just way to big for the amount of air that is actually being used. The real problem Sorry to be so blunt.. but in many cases that real problem is that people just don't care. If you are reading this, that's probably not you, because it shows you care. But most compressed air systems I have seen, people just didn't care. And they didn't care because they didn't know how much that waste cost every single day, week, month, year. On a medium size compressed air system, the yearly energy savings can add up to $10.000 to $30.000 per year! On bigger systems, it can be well over a hundred thousand dollar per year.

Comments

No comments yet…

Log in or create an account to make a comment...