Save your compressor from excessive wear with our information on air compressor filters, so you save money and maintenance in the long run.

Compressor Air filters can be found in two places in your pressured air system: at the air-intake of your air compressor (filtering incoming air) and in the compressed-air piping, between your compressor and your air consumers (filtering compressed air).

We're talking about the first type here. There is more information about the second type here: compressed air filters.

Air intake filters protect the compressor from any dust and dirt which it might suck in.

The intake-air filter is the most important filter on your compressor!

Dust is the number 1 enemy of your

compressor: it will cause wear to the compressor element, valves and other parts. It will also save your compressors oil, oil separator, oil filters and all other moving parts.

Different types of air filters

The compressor air filters need to be cleaned and/or replaced regularly. Normally replacing the air intake filter is part the standard service routine. In very dusty / dirty environments it's better to clean them once in a while (blow the dust off with compressed air).

Save money! An air compressor with dirty inlet filter(s) will reduce the output capacity. You will pay more money through your higher energy bill than the cost of a new filter! And need I say it? Never run your compressor without the air filter connected!

Also, if your compressor is installed in a very dusty or dirty environment (metal workshop with oily air, wood workshop with a lot of dust, sand-blasting workshop, etc) ... do yourself and your compressor a favor: put the compressor in its own room with fresh air, or install ducting to supply the compressor with fresh air.

This will save you a lot of maintenance issues (especially clogged air filters and coolers and over-heating compressors as a result of that).

Air filter housing

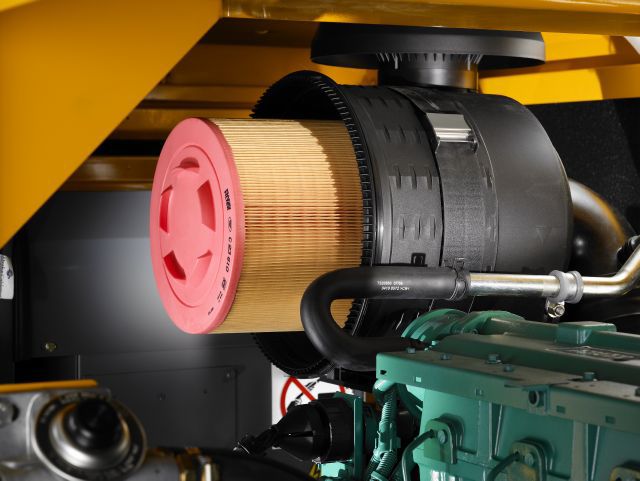

Air filter. Photo: Atlas Copco

Most of the time, the compressors' air filters are inside some sort of plastic housing.

Don't remove or leave open this housing, on many compressors (especially the big ones) it's an essential part of the filtration system:

80% of the dust is removed by cyclone action inside the housing.

The remaining 20% is removed by the air filter itself.

If this is the case, you will find some sort of 'dust drain' on the filter housing. Open it once in a while to remove the dust that accumulates over time.

Air compressor Inlet filter of rotary screw compressor. You can *almost* see the 'cyclone action' happening.

Air filter ratings

A few things are important when selecting an air filter:

Extraction efficiency: the percentage of dust that is removed from the air, for example 99,8% for 1 um (micro-meter) particles.

Flow rate: the air filter is chosen according to the flow rate: bigger flows require bigger air filters. If the flow is too large for the size of the air filter, the pressure drop over the filter will become too high.

Flow resistance / dust capacity: Over time, more and more dust will accumulate in the air filter of your compressor.

This accumulated dust will create a pressure drop (measured in mbar). We don't want to let this pressure drop become too high.

A 25mbar pressure drop over your air filter, will decrease compressor output by 2%!

Bottom-line: change your air-filters in time!

When comparing compressor air filters, be aware that the difference between a 99.8% filter will pass double the amount of dust that a 99.9% filter would do!