Air pressure switch models and options, a perfect pressure switch for every application.

While all pressure switches have the same purpose (switch on or off at a certain pressure), pressure switches come in a lot of different design and types.

Some are very basic and not adjustable, while other are very flexible or have extra options. So, what types of pressure switches are there?Here's a basic overview of the different models and options available.

Note that this is not an or-or list, but rather an and-and list.

Most pressure switches, especially on air compressors will have more than of of the following..

On / off / auto setting

Some pressure switches have an on/off or and auto/off switch. Most of the time this basically is the same thing (the wording depends on the manufacturer).

When you press 'on' or ' auto' it will automatically start and stop the compressor according to the set pressure setpoints.

When you press 'off' it will ignore the setpoints and shut down the compressor.

Air compressor pressure switch with OFF / AUTO selection

Air compressor pressure switch with OFF / AUTO selection

This is basically an all-in-one solution for small compressors.

This type is found mainly on smaller (reciprocating) air compressor, where to motor is directly started and stopped by the pressure switch electrical contacts (see also 'electrical contacts' further down this page).

On many pressure switches, there is no 'on/auto/off' switch. It is always in 'auto' mode, and it will open and close it's electrical contacts according to the pressure.

This type is normally seen on larger air compressor, where the electric motor is started and stopped by external relays/contactors or motor starters.

Electrical contacts / power rating

Inside the pressure switch, there are 1 or more electrical contacts that open and close according to the pressure. The number and power rating (size) of these contacts vary.

Some pressure switches are capable of directly switching on and off the electric motor.

Other pressure switches can only switch on and off a small control signal.

The control signal is then fed into the central controllor or is used directly to switch on and off large contactors or motor starters.

Direct motor switching pressure switches are only seen on smaller air compressor, with relatively small motors, let's say up to 10 kW (about 13 hp).

The power rating of the pressure switch has to exceed the power rating of the compressor motor!

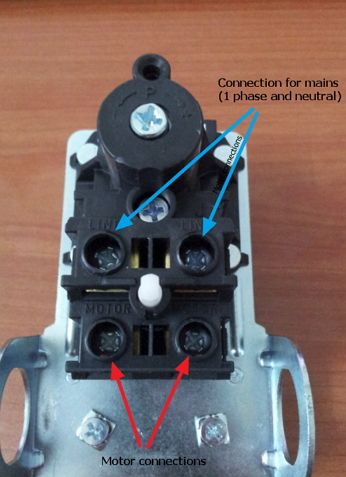

Then there are 3-phase and 1-phase models. 3-phase pressure switches have 3 separate contacts for 3-phase motors. 1-phase models only have 1 set of contacts, for 1-phase motors or for small-current control signal to the main controller (on big air compressors).

Electrical connections on a single phase pressure switch.

Pressure setpoints

The pressure setpoints are the pressure values where the pressure switches form 'on' to 'off and vice-versa. These points are also called the cut-in and the cut-out points.

Most pressure switches on air compressors are set to open (cut-out) at around 7 bar, and close (cut-in) at around 5.5 bar. The difference between the lower and upper setpoint is called the pressure-band or pressure differential.

Regarding pressure setpoints, we can devide pressure switches in the following groups:

- Both upper and lower setpoint can be set individually

- Only the upper setpoint can be set/changed and the lower setpoints follows automaically at a set distance (fixed pressure differential).

- Both upper and lower setpoint are fixed in the factory and can not be changed.

More on this on our setting your pressure switch page.

Also, make sure the maximum pressure rating of your pressure switch exceeds your maximum compressed air pressure.

Most pressure switches only go up to 8 or 9 bar (125 psi), which is quite useless if you have a 13 or even 30 bar compressor.

Mechanical connection

Some pressure switches are designed to mount directly to a tank, other are designed to be installed in a control cabinet and are connected by tubes to the compressed air system.

The physical connection, where the compressed air is connected to the pressure switch is often called 'connection type', 'port type' or 'flange type'.

Most commonly used sizes/types are 1/4", 3/8" or 1/2" NPT female.

Some pressure switches have only 1 connection, some have multiple ports of different sizes, so there is always one that suits your compressor.

Compressed air connection on bottom of pressure switch

Pressure switches with an integrated blow-down valve (see below), will have an extra blow-down connection.

Integrated or optional blow-down valve

On the smaller (home workshop / garage) reciprocating piston compressors, a blow-down valve / unloader valve is used to blow-down air pressure from the compressor discharge line, to facilitate an easy start-up.

It will blow off any pressure in the pipe between the compressor and the receiver when the compressor stops

This blow-down valve is usually integrated in, or in stalled on, the pressure switch.

Sometimes it is fixed inside the pressure switch, but most of the time, the blow-down valve is optional and there is a mounting spot reserved on the bottom or on the side of the pressure switch.

Pressure switch with connection point for blow-down/unloader valve.

Blow-down/unloader valve installed on pressure switch.

But, many pressure switches don't have an integrated or optional blow-down valve, so if you need one on your compressor, pay special attention to this.

The blow-down valve, when installed, is actuated by a small lever inside the pressure switch.

The lever will open the blow-down valve when the cut-out pressure is reached and the compressor stops. More info about this on our air compressor unloader page.

If you're looking to buy a pressure switch, check out my buying a pressure switch page.