An important part of many compressed air systems is the compressed air dryer.

Although not necessary for DIY at home type compressors, when you use many air tools or air-operated machinery, an air dryer is a must have!

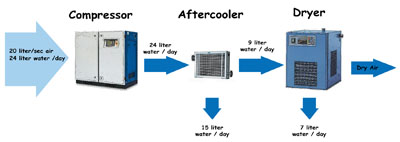

A compressor that sucks in 20 liters of air per second, also supplies 24 liters of water a day!

About 15 of those liters would be removed in the aftercooler.

A further 7 liters would be removed in a (refrigerant) compressed air dryer.

Why use a compressed air dryer?

As the name implies, air dryers are used to dry the compressed air: they remove moisture from the air, resulting in dryer air.

This way, your valuable tools and machinery are protected from water and rust.

But also your piping used to transport the compressed air is protected.

Water? Where is it coming from?

Compressors suck in lots of air and compress it to about 7 times the volume (that is, 7 bar pressure).

The air that is sucked in always contains a little (or a lot!) water.

While the air can be compressed, the water cannot!

Say your compressor suck in 7 cubic meters of air per hour, and it compressed it to 1 cubic meter of air at 7 bar.

The 7 cubic meters of sucked-in air contains water (like all the air around us). After compression, there is only 1 cubic meter of air, but with still the same amount of water!

Hot air can contain more water than cold air. That's a fact, just believe me :).

When the air exits the compressor, it is hot and wet. 1 cubic meter hot compressed air still contains the same amount of water that the 7 cubic meters cold air did before they were compressed.

Normally, the compressed air goes through an aftercooler which will cool down the air to about 20 degrees higher than room temperature (about 40 degrees Celsius).

During the cooling-down, a lot of water will condensate and will float with the air in the form of small drops.

At the end of the after cooler, there should be a condense water trap, which will remove all the water that has formed.

Now the air leaves the compressor at about 40 degrees, but saturated with water. It's right at the dewpoint temperature (dewpoint = temperature at which condensate forms. That is when the air reaches 100% relative humidity and can't hold any more water).

For every degree that your compressed air cools further, more water will condense! And considering that the air that leaves the aftercooler of the compressor is about 20 degrees warmer than room temperature... you have a problem! :)

A compressor that delivers 20 liters of air per second, also supplies 24 liters of water a day!

About 15 of those liters would be removed in that aftercooler. A further 7 liters would be removed in a (refrigerant) dryer.

If you didn't have a compressed air dryer, most of those 7 liters would end up in your compressed air piping, your receiver and in your tools and machinery!

How to dry compressed air

There are a few ways to dry compressed air.

- You can lower the temperature and then re-heat it. Condensate will form at the low temperature, where the water can be discharged. After re-hearting, the air is dry. This process is used in refrigerated compressed air dryers.

- Over compression. The over compressed air is cooled. Any condensate formed is removed and then the air is expanded to normal working pressure. Expensive and seldom used.

- Absorption. Water in the compressed air is chemically bound to an absorption material. The water dissolves in the material. Both the material and water is then discharged.

- Adsorption. The water 'sticks' to the surface of the adsorption material (desiccant). The desiccant is 'regenerated' to remove the water again. This process is used in desiccant compressed air dryers.

Refrigerated compressed air dryers

Refrigerated compressed air dryers use a small refrigerator to cool down the compressed air to about 3 degrees Celsius.

At this low temperature, condensate will form which is removed by a condensate trap. When all the water is removed, the air is re-heated to room-temperature. Your air is now dry and will not form any water as long as it stays above 3 degrees Celsius.

More information about refrigerated compressed air dryers

Desiccant compressed air dryers

Desiccant air dryers use desiccant to remove the water from the compressed air. Basically, the water will ‘stick’ to the surface of the desiccant, resulting in dryer air. Every once in a while, the desiccant is re-generated. This is done automatically by the dryer. It blows dry, hot air through the desiccant to remove the water. The desiccant is now ready to do its job again. Desiccant compressed air dryers can reach much lower dew-points, up to -70 degrees Celsius.

More information about desiccant compressed air dryers

Which one?

Which one is right for you?

It mainly depends on what you use the air for.

Normally, a refrigerated compressed air dryer will do. It will lower the pressure dewpoint to about 3 degrees Celsius. This

means, that as long as the air temperature doesn't fall below 3 degrees Celsius, your safe.

Do you need lower dew points? For example, because your compressed air piping runs outside, or you need the air for a special purpose where very dry air is needed?

Then you need a desiccant compressed air dryer..

Considerations when buying a compressed air dryer

When shopping for a compressed air dryer keep in mind that the capacity (liters per second of air) and maximum pressure must be right for your compressor.

Also, make a choice what kind of dryer is right for you. Refrigerated air dryers are the most economical option energy-wise.

Also keep in mind that the purchase price and the yearly energy-costs are NOT all of your expenses. There are a few extra 'hidden' costs!

Hidden cost one: extra pressure drop. An air dryer might cause about 0.3 bar pressure drop in your compressed air system. Basically this means that you have to run your compressor at a higher pressure. This of course will result in more energy consumption by your compressor.

Secondly, if you opt to buy a desiccant compressed air dryer, check the way that the desiccant is re-generated.

If it is done with compressed air, this will consume about 15 to 20% of the dryer's maximum capacity. That's a lot of expensive compressed air!

I have made a list of popular compressed air dryer manufacturers to help you find one that is right for you.