Why do compressed air systems need an air receiver anyway? They are bulky, take up a lot of room, costs money.. and they don't do much, or do they? Air receivers acts as a buffer, it stabilizes the air pressure and they are a backup storage for peak demands. Why would we want this? First, let's take a look at what influences the pressure in a compressed air system to begin with.

The pressure in a compressed air system

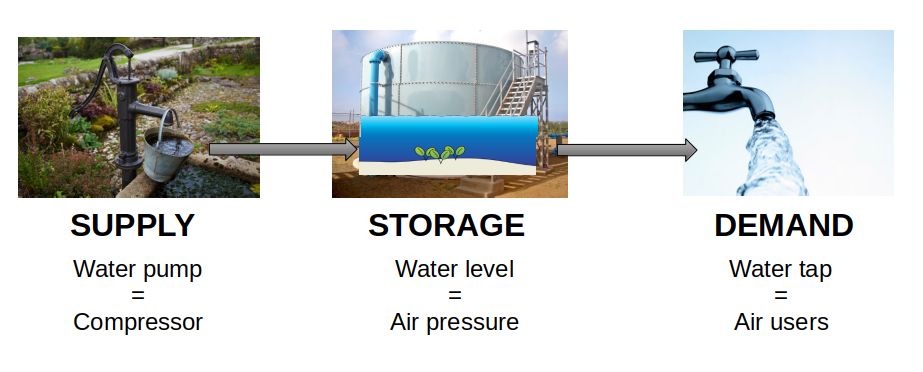

A compressor doesn't just output a certain pressure. It output a certain flow of compressed air (the compressor capacity) up to a certain pressure (the compressor's rated pressure). The easiest way to understand what happens in your compressed air system is to compare it to a water tower.

Just like our compressed air system, the system has a supply (a water pump), storage (the water tower) and demand (you taking a shower). If we pump in water, the water level in the tower will rise. When we use water, the water level will fall. If we pump in water, and use water at the same time, what happens? It depends on how much water we pump in, and how much water we use at the same time. If we pump in more water than we use, the water level will still rise.

If we use more water than we pump in, the water level will drop. Very easy, right? The same is true in our compressed air system. The pressure in a compressed air system is the result of the amount of air we have pushed into the system, and the amount of air we have taken out. ### A slow, quiet system saves energy

When it comes to compressed air receivers... big is better!

When it comes to compressed air receivers... big is better!

Most air compressors work with a load/unload capacity control. That means they either put out 100% of their capacity, or nothing. In our water tower example, this means the water pump is running at 100%, or is stopped. If we don't have any buffer in our compressed air system, the pressure would rise very quickly as soon as the compressor starts pumping air. It's similar to a very narrow water tower. If we start the pump, the water level will shoot up. Then, if the compressor stops (because the pressure shot up, so we reached our desired pressure), the pressure falls down fast as well.

In our narrow water tower example: there's little storage of water, so if we use water, we quickly run out, and the pump must start again. This makes the compressed air system very unstable. The compressor will load/unload quickly and the pressure will constantly fluctuate.

Now compare this to a compressed air system with a large buffer tank. When the compressor starts pumping air, it takes some time before the required pressure is reached - which is a good thing! It's like a big, wide water tower. We need to pump in a lot of water to make the water level rise. In a typical compressed air system, it's normal this takes a few minutes, at least (with no air consumption).

The bigger the buffer is, the longer it takes to fill up, but when we use air, it also takes longer before the pressure drops. And that's great! It makes the whole system slow. Which is good, because it gives the air consumers as steady supply of compressed air. And it's also very good for your air compressor. Since cycles are longer, the compressor starts and stops less frequently, which reduces wear on the air compressor. It also saves energy - because the air compressor cycles less often, there is less air blown-off, there's also less running unloaded (if the buffer is big enough and the compressor has a chance to completely stop) and it also makes sure that a second (trim) compressor only starts up when really needed, and not every time the pressure dips for a few seconds.

But the biggest plus is that a big storage allows you to reduce the unload pressure of the compressor - a potential huge energy saving! With a small air receiver, pressures go up and down quickly - this means you are forced to set the compressor setpoints higher, and further apart, to make sure the air consumers always receive a certain minimum pressure and to make sure the compressor doesn't cycle every few seconds.

With a big storage, changes in pressure are very slow. This allows you to set a small pressure differential (difference between load and unload setpoint) and also allows you to set the overall pressure lower - since the compressor has plenty of time to startup before the pressure drops too low.

Remember: lowering the compressor setpoint by 2 psi will lower your energy bill by 1% or, lowering the compressor setpoint by 0.1 bar will lower your energy bill by 0.7%. ## Storage for peak demand

Air compressors should be sized according to air demand. At least, there should be more capacity than the average consumption over a certain period of time. There will be times of the day where there's more demand, and times when there's less. We need to size the compressor for the 'average peak' demand that's likely to happen, to make sure we can maintain pressure.

With average peak demand, I mean the average demand over a few minutes, 10 minutes, or more, depending on how big of a problem drops in pressure are. In these periods of average demand can be peaks of super high demand - higher than the capacity of the air compressor. The air receiver acts as a buffer for these peaks. Since the air usage is higher than the air supply during these moments of high demand, air pressure will drop.

But if we make the air receiver big enough, it holds enough air to supply to excess use. The bigger the air receiver is, the slower the pressure will drop, and higher the chance that the peak demand stops before the pressure drops too low.

Helps to cool down the air

Air coming from the air compressor is hot and often contains a lot of water vapor.

Always have an automatic drain at the bottom of your air receiver

Always have an automatic drain at the bottom of your air receiver

Inside the air receiver, the air will cool down and water vapor condenses into liquid water. For this reason, every air receiver must always have an automatic condensate drain at the bottom. This initial cooling helps to remove water from the compressed air. It also increases the efficiency and electricity use of downstream compressed air dryers. This will also lower other contaminations, like oil, since at lower temperatures, oil vapor concentration will be lower and compressed air filters are more efficient. ## Final thoughts

Conclusion

We've seen some very, very good reasons to install a big air receiver in your compressed air system. While it might be tempting to look at the price - bigger receivers are of course more expensive - it's almost guaranteed that you will make back that money in reduced energy costs, reduced maintenance and better air quality.

Actually, air receivers can't be big enough. Are wondering which size is right for you? Get the bigger one!

Comments

nice once again

agreed

Log in or create an account to make a comment...